PROHOLD® horizontal and vertical fixtures allow an infinite number of configurations to safely and productively hold your workpiece. This is accomplished through multiple-jaw, self-centering, OD and ID chucking, as well as 2-Jaw vise capability.

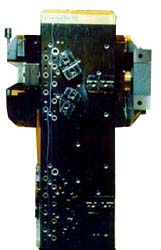

Custom PROHOLD® with modular mounting holes

Custom PROHOLD® with modular mounting holes

Customers have doubled their production with PROHOLD® due to our versatility and repeatability. Part-to-part accuracy has increased with a tangible decrease in scrap. Fewer machines are needed to run the same volume for a geometric family of parts.

8-Chucking Station

8-Chucking Station

Key Features:

• Easy changeover for large or small repetitive production runs means that our jaws will be in the exact location you need them – every time. Simply install the jaws, call up the part program, load the part and start the machining cycle.

• Internal right angle drive mechanisms on PROHOLD® chucking stations allow the unobstructed use of the full face of each side of the fixture as the chuck wrench socket is not in the face of where the part is loaded. Standard configurations on the master jaw faces allow the use of commercially available hard or soft jaws.

• When the PROHOLD® fixture is permanently aligned and secured on the machine tool pallet, you have a permanent, repeatable, zero-baseline grid off the chucking centerlines, making programming quick and easy with stationary X, Y and Z coordinates.

• All internal components are hardened and sealed to protect them from foreign matter (chips, coolant, etc.). All exposed surfaces are finished in black oxide and gold anodizing.

• PROHOLD® fixtures are available for all shapes and sizes of parts to be machined. Irregular contours can be machined into full-surround soft jaws to hold castings or other non-round workpieces. Long workpieces, like shafts and tubes, can be passed through the center of the PROHOLD®.

Whatever your needs may be, PROHOLD® has just the fixture to solve your manufacturing requirements. If you don’t see what you need call us – we can design and produce exactly what is necessary to get your job done!

For more information regarding Manual Chucking Tombstones please fill out the form below and a representative will contact you as soon as possible.